Thursday, March 31, 2022

Aluminum 650 single speed MTB frame for a local

The seat stay yoke is also from Ahrens.

Monday, March 28, 2022

Steel gravel frame going to Canada

Another feature is the oversized seat tube for a 31.6 mm dropper post with internal routing. The frame also has rack and fender mounts.

The customer sent an aluminum stem to be painted to match the frame. This one is a Ritchey.

The whole package is finished off with a copper Jen Green headbadge.

Sunday, March 27, 2022

Steel rim brake 650 gravel frame and fork going to Kansas

Since there's no big hills where this bike will be ridden there wouldn't be much to gain from having diac brakes. Also, the customer has wheels and parts to build up the bike already so this way he does not have to shell out a bunch of cash to build his new gravel bike. With room for 45 tires, this bike should handle the long gravel stretches in Eastern Kansas well but still be pretty quick on the pavement.

There's a lot of nods to tradition with the level top tube, crowned fork and road cable routing. I think I have a lot of the same parts in my spares so you never know- I might build something like this up as well- first I have to sell a few bikes to make room !

Friday, March 18, 2022

Fillet brazed road frame with crowned fork for bay area rider

This frame is a copy of a Saturn frame made by the late John Padgett about 30 years ago. I think that the Saturns were some of the nicest fillet brazed frames of the last century, particularly the tandems. I hope that this one looks as nice when it is all painted and assembled as the original bike. The only departure from the Saturn is that this bike has a 1-1/8" steerer - a small concession to modernity-essentially making it easier to source the headset and stem. It will also stiffen up the front end a taste.

The customer even supplied NOS Shimano SF-22 dropouts- the dropouts of choice back in the '80's. They were tidy looking and durable. The only issue I had was that the angle between the seat and chain stays didn't work with this tall of a frame so I had to do some bronze filling to make the seatstay intersection look a bit nicer. It was a fun project but very labor intensive- the more I looked at it , the more finishing I wanted to do. Today I was able to look it over and say to myself : "pretty good for not having done one in about 15 years plus !"

Saturday, March 12, 2022

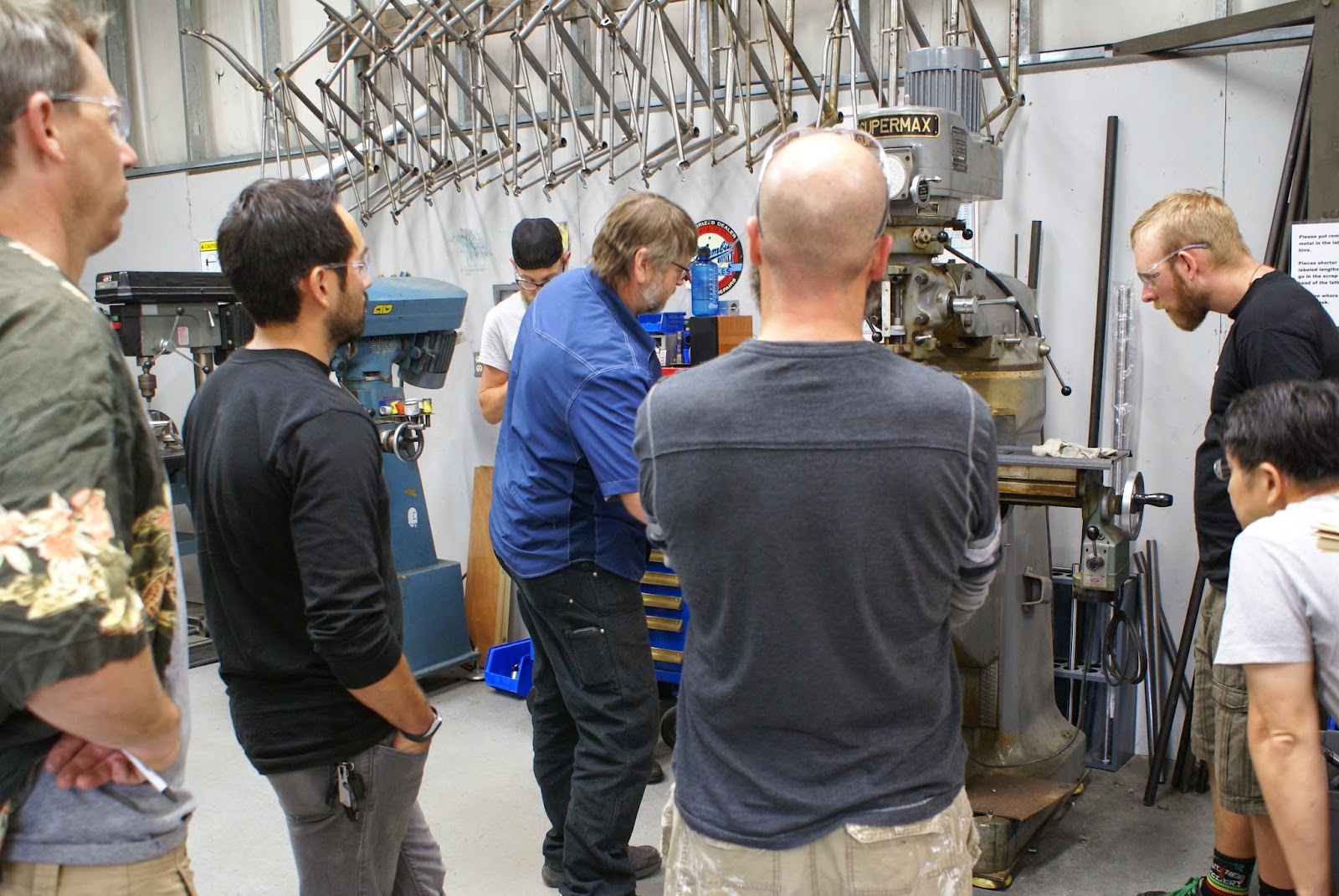

The end of an era : UBI frame building school

A few months ago the last UBI frame class was held. Since around 1992 United Bicycle institute in Ashland, Oregon had been holding classes in frame building that were arguably the best anywhere in the country , if not the world. Nobody else had a facility and a system that was so well thought out and so complete - this was a factor of not just the founder Ron Sutphin's input but the experience of the staff and all who came to the school to teach. There were a lot of cooks in this kitchen over the years and the result was a truly all-encompassing approach to teaching people how to build their first bicycle frame.

The class starts out pretty low key but in a matter of days turns into a stressful pressure cooker for many of the students. The frustration with what is not a simple or easy process was a lot for your average student at UBI to deal with. The staff-including Ron- also had to deal with stressful situations, constantly trying to keep the students on track and on schedule. I know this as I was a guest instructor at UBI for nine years. I learned quite a bit from the experience and value my time at UBI a great deal. I think that I am better at my craft for having been part of the UBI family in my limited way, only one class per year, usually in August. I deeply regret that there will be no more classes in frame building at UBI.

The whole frame building fever really got going around the late 1990's. UBI already had building classes but the demand for the classes started getting to be too much for the small Ashland school to handle. After a number of years UBI opened a second school in Portland to handle some of the volume. This lasted for around a decade and after awhile the demand for the classes started waning. Around six years ago the Portland campus stopped having the classes. Once Covid hit the writing was on the wall for the frame building program-only half size classes were permitted and the economics to keep the program going were not adding up. I can't say for certain what was the complete reason for the school to end the program but there were many difficulties in keeping it going- probably too many.

Now that these amazing classes are no more , it signals kind of an end to a period marked by huge enthusiasm for the craft of building - both at the school , on the internet and at the bike shows and by the bike riding public. People still order frames and many builders are busier than ever. The difference is that the rabid curiosity about the building process seems to have run its course. It might come back and there might be need for a frame building school again but one thing for certain, it won't be UBI - that ship sadly has sailed. I am glad that I was a minor part of the program as it was truly a rewarding experience for me and it taught me ways to do things that I had not fully thought about, even after building 100's of bicycle frames for several decades. I want to thank Ron, Denise ,Gary ( yeah, even you Gary..), Rich, Nate, Mike, Jeff and all the UBI crew for letting me be part of the whole experiment. It was some of the best times of my frame building misadventure- I could count on every August to be a break from my own shop and a chance to do something to bring the next generation into the craft.

Friday, March 11, 2022

Steel gravel/commuter for Austin, Tx.

This one has a fairly stout mix of Columbus Zona to withstand the rigors of commuting and long dirt road events. There's routing for a rear light and three bottle mounts.

The frame will be paired to an Enve Adventure fork and will be able to take 700x47 tires. It also should be OK with 650x2" tires if you don't mind a little pedal scrape in the turns.

Tuesday, March 8, 2022

Steel Gravel frame for Marin county.

This frame is all Columbus Zona so it will be pretty durable over the long run but it is definitely not the heaviest steel that I build with. I have not weight the frame yet but it is probably somewhere in the 4 lb. 6 oz. range - not bad for a steel frame in this size.

Wednesday, March 2, 2022

Steel 29er SS/Geared

I also used a head tube that will take an integrated drop-in headset. This is the style I use on nearly all my aluminum frames but rarely use on steel. The advantage of this style is that headset bearing replacement is easier and the head tube winds up being a bit longer - this works well on bikes like this where the tubing is fairly large diameter and head tubes are usually short enough to make a small landing place for the top and down tube to be welded to. Frequently the top and down tube will overlap, creating a more difficult mitering and fit-up situation.

This frame also has internal dropper post routing. The rocker dropouts are angled such that the rear brake is down tube routed rather than top tube routed. There are several inserts available for the rockers so that post,IS or even flat mount brakes will fit. The rocker dropout is usually a $ 130 upgrade on the stock steel frame price.